hydraulic oil seal sizes

Next, we discuss the 40% figure, which can denote the allowable leakage rate for particular types of oil seals. Leakage can severely impact the overall performance of mechanical systems, leading to reduced lubrication and increased wear on components. A reputable oil seal must minimize leakage to a level that is often benchmarked at around 40% of the maximum allowable threshold for that system. Manufacturers pour significant resources into developing materials and designs that can achieve this standard, as minimizing leakage not only conserves lubricant but also enhances the efficiency and longevity of the machinery.

22 40 7 oil seal

38x52x7 oil seal. Common materials include rubber compounds like NBR (Nitrile Butadiene Rubber), FKM (Fluoroelastomer), or HNBR (Hydrogenated Nitrile Butadiene Rubber), each with its own unique properties suited for different operating environments. These materials provide excellent resistance to oils, chemicals, and temperature extremes, ensuring the seal's functionality in a wide range of industrial settings.

38x52x7 oil seal. Common materials include rubber compounds like NBR (Nitrile Butadiene Rubber), FKM (Fluoroelastomer), or HNBR (Hydrogenated Nitrile Butadiene Rubber), each with its own unique properties suited for different operating environments. These materials provide excellent resistance to oils, chemicals, and temperature extremes, ensuring the seal's functionality in a wide range of industrial settings.

hydraulic lip seal. By creating a tight seal between the piston and cylinder, these seals help to minimize the loss of hydraulic fluid and prevent contamination of the system.

35x47x7 oil seal.

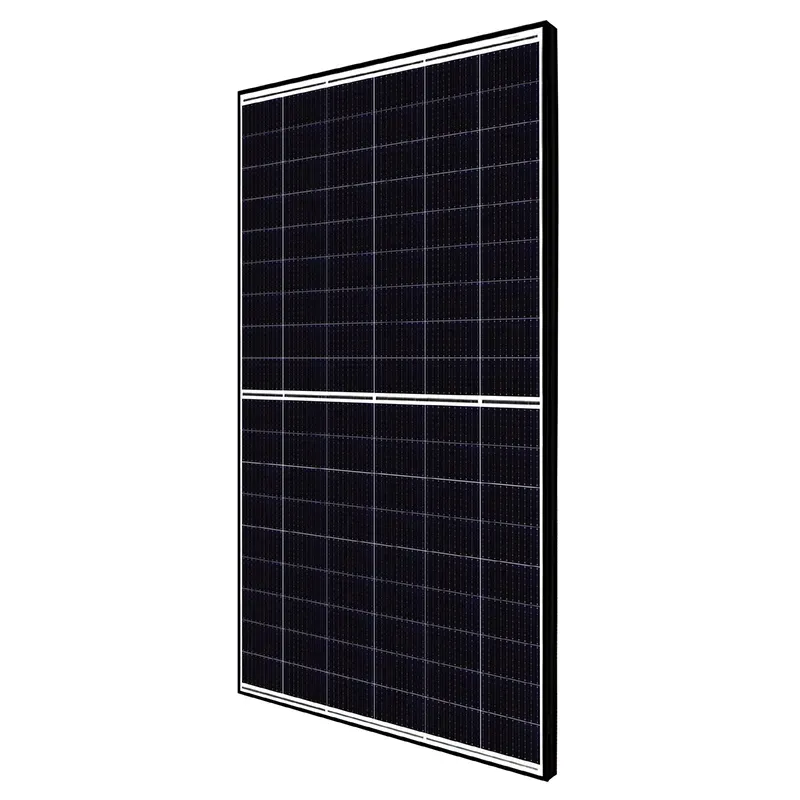

2. Improved Durability Bifacial mono PERC panels are typically made with robust materials that enhance their longevity. They are less susceptible to degradation under harsh weather conditions, and their design minimizes the impact of shading events, which can be detrimental to traditional solar panels.

bifacial mono perc